- Why Polymer Concrete Manholes?

Polymer concrete manholes are the best products till date that can be used to build a completely corrosion resistant and leak proof sewer system.

- Polymer Concrete Vs. Concrete:

Concrete manholes are formed using cement, aggregate and water. The sulphuric acid (H2SO4) which is present in any sewer system devours the cement leaving behind only the aggregate.

On the other hand, polymer concrete manholes do not utilize any cement nor water in their production. They are formed using unsaturated polyester resin, sand, gravel, and mineral fillers. This unique combination of products gives polymer concrete manholes their outstanding corrosion resistant and elastic properties.

- Design and Parts of Al-Qudaibi's Manhole Systems:

All of Al-Qudaibi's manhole's are made according to the customers' requests and specifications.

Table 1.1 displays the typical specifications of Al-Qudaibi's manholes:

Type |

DN |

ID(mm) |

Wall Thickness TW(mm) |

Maximum Pipe Opening(mm) |

1 |

1000 |

1000 ± 6 |

50 |

400 |

2 |

1200 |

1200 ± 10 |

60 |

600 |

3A |

1500 |

1500 ± 10 |

70 |

800 |

4A |

1500 |

1500 ± 10 |

90 |

800 |

4B |

1800 |

1800 ± 12 |

90 |

1000 |

4C |

2000 |

2000 |

100 210 |

1200 |

Table 1.1

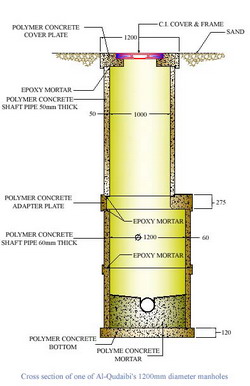

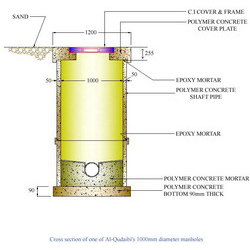

The following two figures (fig. 1 & fig. 2) display two different complete manholes. Fig. 1 displays the standards of DN 1200 and includes the shaft, adapter plate, cover plate and cover whereas Fig. 2 displays the standards of DN 1000 without the adaptor plate and cover.

| Figure 1 - 1200mm Dia. Manhole | Figure 2 - 1000mm Dia. Manhole |

- Ease and Speed of Installation:

Al-Qudaibi's manholes are delivered to the construction site as one complete piece. Even in the event of deep installations, additional manhole sections called shafts are made and butt-jointed to the manhole and again, delivered as one complete piece. The installation process can be completed in a matter of few minutes. This process consists of unloading the manhole, lowering it into the trench and placing it on a clear layer of sand or aggregate. It is then connected to the installed sewer system through connections which have already been installed to it at the factory.